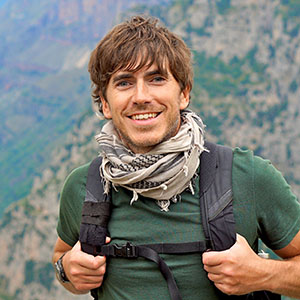

Oimo, the Catalan company that has created an alternative material to plastic.

"Be the change we want to see" It is the phrase that we have heard and read the most in the demonstrations of young people who fight for climate change around the world. But from theory to practice there can also be a whole world. There are, however, cases in which it is shown that this is not the case.

Three years of hard work ended (or started a new stage) for Albert Marfà when he managed to make six can wrappers out of bioplastic and “by shaking them non-stop” they held on perfectly . It was the first step for Oimo, a company based in Barcelona that has created an alternative material to plastic that could be of great help in reducing our waste.

“The invention arose from a concern that I had in wanting to find a alternative to conventional plastic for packaging , specifically their long-term degradation in our oceans and the damage they cause as a result. In fact, there are already recent studies that show how plastic is ending up in our food chain, apparently we eat a credit card a week in weight of microplastics”, Albert, the founder of Oimo tells Traveler.es.

Edible Plastic it was the beginning of some investigations that he began as a university student in London. “I started this startup as a spin off of Brunel University London, with my partner and CMO Clara Hardy with the motivation of be the change we wanted to see and try to find solutions to the problem we have with plastic”. Later they extended the team to two biopolymer engineers, two Spanish plastic technical institutes and staff in China.

Oimo plastic is created from algae, sugars and vegetable oils.

A MATERIAL THAT DOES DEGRADE IN THE OCEAN

The main quality of the biodegradable material created by Oimo is that yes it degrades in the ocean . This is the big difference with other bioplastics already created at an industrial level.

“What we have created is a new generation of completely new biomaterial or bioplastic . To put it in context, bioplastics already existed, but only a few have been commercialized, the most used in the market today is PLA. What many end users are unaware of is that PLA only biodegrades industrially, which means that it will only decompose if it is taken to an industrial composting plant prepared to treat it (it has to be subjected to certain temperatures, humidity, ph, etc.). If it ends up leaking into the oceans, it will never completely biodegrade, it will only produce more microplastics, ”he explains to Traveler.es.

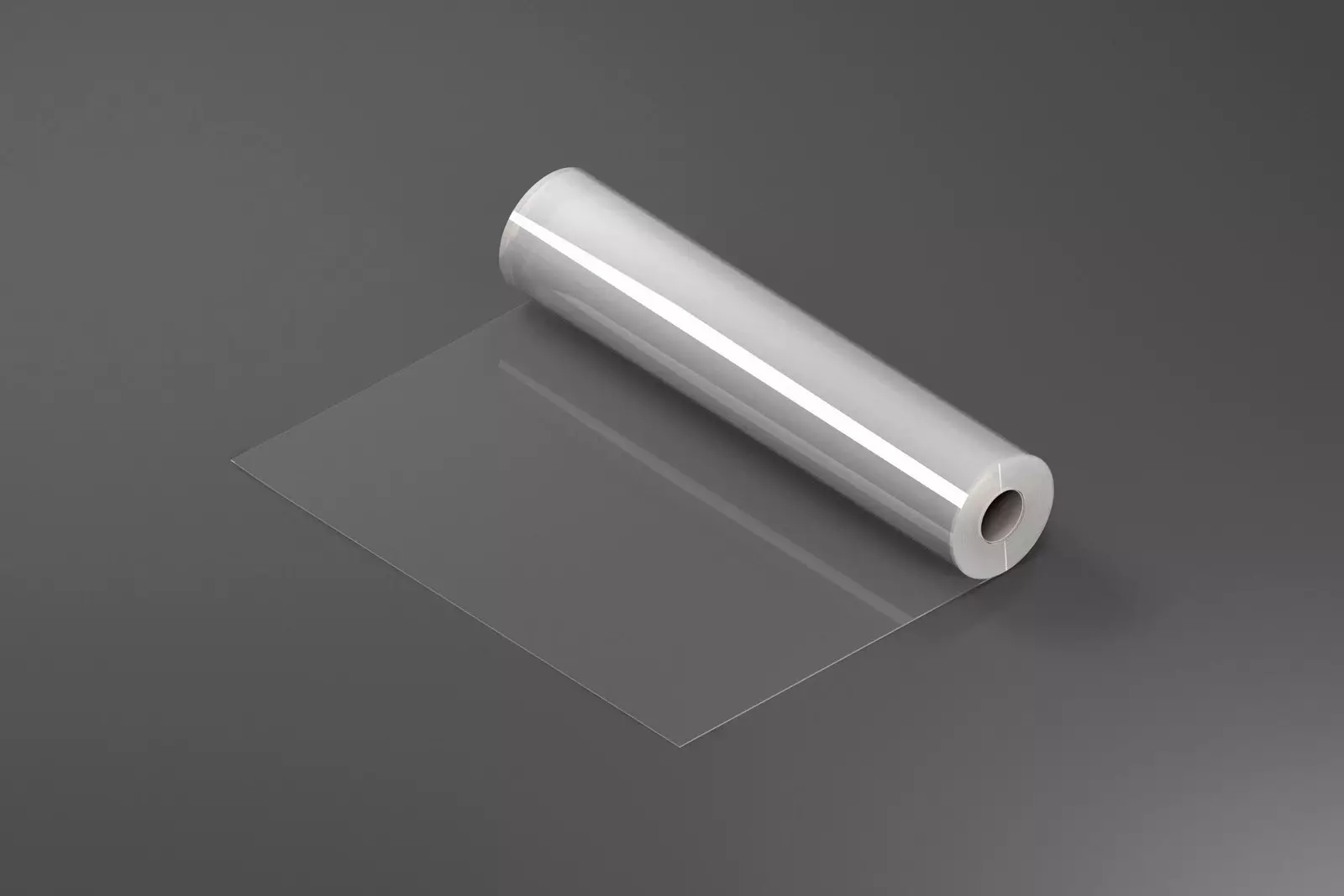

This is the material created by Oimo.

Another great quality is that fits into the machinery that companies already have to produce normal plastics , meaning that these companies would not have to invest in new machinery to be able to use this material, which is made from algae, sugars and natural vegetable oils that are not harmful to marine fauna and flora.

In addition, all kinds of packaging materials can be manufactured with the Oimo product. “The idea is that it can have as many uses as possible. For now we have wanted to replicate two of the most used plastics that would become the LDPE (classic flexible plastic) and the HDPE or PP (classic rigid plastic). Some products that we have already come to process in industrial machinery would be both rigid packaging and flexible films”.

Oimo has created the wrappers that hold and wrap the cans.